GY Photovoltaic prefabrication chamber, also known as prefabricated cabin for intelligent substations, is designed to further deepen the technology of intelligent substations, unify construction standards, improve project construction quality, safety, and efficiency. The State Grid Corporation of China has initiated the construction of standardized and distributed intelligent substations, proposing the technical principles of “standardized design, factory processing, mechanized construction, and assembly construction.” This represents an advancement in standardized construction, effectively shortening the construction period, improving project quality, reducing construction cycle costs, and promoting environmental protection. It enhances the efficiency of intelligent substations, increases the construction capacity of power grids, and steers substation construction towards a path of high technological content, low resource consumption, low environmental pollution, and fine construction.

Key Features

The fully prefabricated cabin assembly substation changes the traditional layout of electrical systems, civil engineering design, and construction methods for substations. The construction of substations is carried out in two main phases: factory production of prefabricated components and on-site installation. Standardized design, modular combination, industrialized production, and intensive construction make substation construction more environmentally friendly and refined.

1. In civil engineering: It improves the traditional layout of electrical systems, adheres to the principles of building energy conservation,material conservation, water conservation, and land conservation. The goal is to make the building structure lightweight, using on-site rapid assembly processes to shorten the construction period.

2. In electrical aspects: It requires the development of six major standard systems, including general substation design, component processing detailed drawings, factory production processes, on-site assembly processes, construction cost quotas, and assembly construction control.

3. The construction mode of fully prefabricated assembly substations requires the support of modern prefabricated parts and steel components. It redefines the traditional mode, and the prefabricated cabin has become an important part of power development.

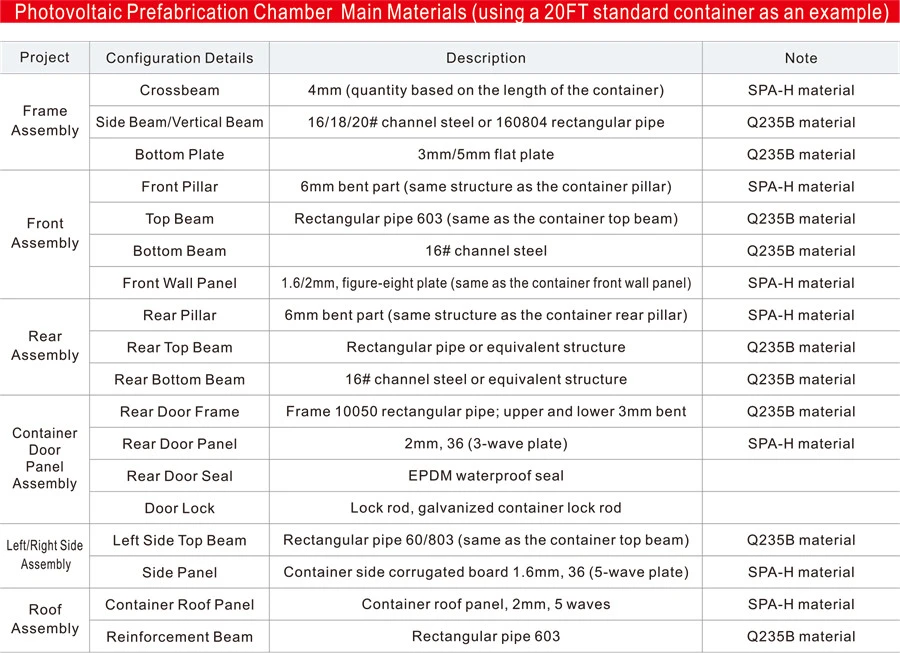

Our photovoltaic prefabrication chamber mainly uses SPA-H weather-resistant steel (B480) for exposed surfaces. Most photovoltaic prefabrication chamber manufacturers on the market use Q235B ordinary carbon steel plate. Weather-resistant steel, also known as atmospheric corrosion-resistant steel, is a low-alloy steel series between ordinary steel and stainless steel. Weather-resistant steel is formed by adding a small amount of corrosion-resistant elements such as copper and nickel to ordinary carbon steel. It has characteristics such as high strength, toughness, plasticity, formability, weldability, abrasion resistance, high temperature resistance, and fatigue resistance similar to high-quality steel. Weather resistance is 2-8 times that of ordinary carbon steel, and coating performance is 1 .5-10 times that of ordinary carbon steel. At the same time, it has rust resistance, which makes components corrosion-resistant, prolongs life, reduces thinning and consumption, and saves energy.